Specs at a glance

-

Accuracy

up to 0.4 mm

-

Process temperature

-200°C...200°C

(-328°F...392°F) -

Process pressure / max. overpressure limit

6 bar abs

-

Max. measurement distance

22 m (72 ft)

-

Main wetted parts

316L, AlloyC276, PTFE

Field of application

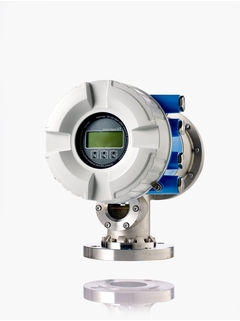

The intelligent tank gauge Proservo NMS83 is designed for high accuracy liquid level measurement in custody transfer and inventory control applications with NMi- and PTB-approvals. It meets all requirements for hygienic applications. It fulfills the exact demands of tank inventory management and loss control and is optimized in regards of total cost saving and safe operation.

For high accuracy custody transfer measurement in beer, whiskey, wine and sake.

Process connections: Flanges

Temperature: -200 to +200°C (-328 to +392°F)

Pressure: 0 to +6bar (0 to +87psi)

Maximum measuring range: 22m (72ft)

Accuracy: ±0.4mm (±0.02")

International explosion protection and custody transfer certificates, overfill prevention WHG, SIL

Benefits

-

Hardware and software developed according to IEC 61508 up to SIL3 (in homogeneous redundancy) for high level of safety

-

Maximum reliability through accuracy up to ±0.4mm (± 0.02")

-

Developed according to international metrology recommendations such as OIML R85 and API MPMS

Local and country-specific certifications like NMi or PTB for custody transfer applications

-

Simplified installation and trouble-free operations due to easy connection to major DCS systems via open protocols

-

Measurement of interfaces between up to three liquid layers, tank bottom, spot, and profile densities

Videos

Xpert selection

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

Predecessor

-

Measuring principle

Servo / Float Tank Gauging

-

Characteristic / Application

Servo Tank Gauging: High precision measurement for liquid level,

interface, spot density and density profile for hygienic applications -

Specialities

Custody transfer level measurement

Interface measurement

Spot density, density profile measurement -

Supply / Communication

85-264VAC

52-74VAC

19-64VDC -

Accuracy

up to 0.4 mm

-

Ambient temperature

Standard:

-40°C…60°C

(-40°F...140°F)

For calibration to regulatory

standards:

-25°C…55°C

(-13°F...131°F) -

Process temperature

-200°C...200°C

(-328°F...392°F) -

Process pressure / max. overpressure limit

6 bar abs

-

Main wetted parts

316L, AlloyC276, PTFE

-

Process connection

Flange:

DN80/3" / DN150/6" -

Max. measurement distance

22 m (72 ft)

-

Communication

Outputs:

Fieldbus: Modbus RS485, V1, WM550

HART, BPM and TRL/2 (via GE option)

Analog 4-20mA output (Exi/ Exd)

Relay output (Exd)

Inputs:

Analog 4-20mA input (Exi/ Exd)

2-, 3-, 4-wire RTD input

Discrete input (Exd, passive/ active) -

Certificates / Approvals

ATEX, FM, IEC Ex, EAC, JPN Ex, KC Ex,

INMETRO, NEPSI, UK Ex -

Safety approvals

Overfill protection WHG

SIL -

Design approvals

EN 10204-3.1

NACE MR0175, MR0103 -

Metrological approvals and certificates

OIML, NMi, PTB

-

Options

Redundant fieldbus

Weather protection cover

CIP (Cleaning in Place)

Relief valve

Gas purging nozzle connection

Pressure gauge

Cleaning nozzle connection -

Application limits

Stilling well or guide wires for turbulent

application

Recommend PTFE displacer for high

viscosity application

Interface measurement requires min. difference of 0.100 g/ml

between layers

-

Measuring principle

Servo / Float Tank Gauging

-

Characteristic / Application

Servo Tank Gauging: High precision measurement for liquid level,

interface, spot density and density profile for hygienic applications -

Supply / Communication

85-264VAC

-

Ambient temperature

Standard:

-40°C…60°C

(-40°F...140°F)

For calibration to regulatory

standards:

-25°C…55°C

(-13°F...131°F) -

Process temperature

-200°C...200°C

(-328°F...392°F) -

Process pressure

6 bar abs

-

Wetted parts

316L, AlloyC276, PTFE

-

Output

Outputs:

Fieldbus: Modbus RS485, V1, HART

Analog 4-20mA output (Exi/ Exd)

Relay output (Exd)

Inputs:

Analog 4-20mA input (Exi/ Exd)

2-, 3-, 4-wire RTD input

Discrete input (Exd, passive/ active) -

Certificates / Approvals

ATEX, FM, IEC Ex, NEPSI, EAC

-

Options

Redundant fieldbus

Weather protection cover

CIP (Cleaning in Place)

Relief valve

Gas purging nozzle connection

Pressure gauge

Cleaning nozzle connection -

Specialities

Custody transfer level measurement

Interface measurement

Spot density, density profile measurement -

Measuring range

22 m (72 ft)

-

Other approvals and certificates

EN 10204-3.1

NACE MR0175, MR0103

OIML, NMi, PTB

-

Measuring wire,PFA>316L,0.4mm dia.16m

-

Meas. wire/tape

Drawing numberOrder code8671659149 -

-

Terminal set, I/O module, Push-in, TG

-

Terminals

Drawing numberOrder code3771324756 -

Choose from our suggested options

-

-- selected coding-- selected label99.999,00<%label%>

-

Looking for more options? Please use the individual configurator to continue

-

-- selected coding-- selected label99.999,00<%feature%>

-

<%label%>99.999,00

-

Looking for more options? Please use the individual configurator to continue

-

Process Connection

-

<%label%>99.999,00

-

<%label%>99.999,00

-

-

<%feature%><%coding%><%label%>

- CAD drawings CAD drawings

- CAD drawings

-

Prices per piece

-

<%range%><%price%>

-

- Optional add-ons

Individual configuration

Often bought together

Accessories