Thermocouples (TCs) work by connecting two different metals or alloys. Due to differences in heat conductivity and electron movement, a small voltage is produced relative to the temperature difference between measuring junction and reference junction, known as the thermoelectric or Seebeck effect. The measurement or hot junction is where the metals are welded together and the reference or cold junction is where the voltage is measured. As the measurement is differential, the cold junction’s temperature must be known to determine the actual temperature.

The voltage produced by thermocouples is very small, requiring precise electronics in the temperature transmitter. Standardized thermocouple pairs include type K (Chromel and Alumel), which is popular and produces a 45 mV signal at a 1000 °C (1832 °F) difference. For higher temperatures, noble thermocouples like type S (Platinum and Platinum-Rhodium) are used, producing a 15 mV signal at 1500 °C (2732 °F).

Studies show that thermocouples can drift 3-6 % per year. This drift occurs because the Seebeck voltage, produced by the difference between two alloys, decreases over time as the materials mix. This can happen through gas phase or diffusion, affecting the accuracy of the measurement. The only solution for maintaining temperature measurement accuracy is to regularly replace TC sensors in critical applications.

For high temperature measurement we recommend thermocouples! High temperature means above 600 degrees Celsius. They are quite easy, you see here in this antique measuring instrument, there's no battery, there's nothing. Just the thermocouple. We will see two welded metals and if I heat it up you see the analog instrument is rising up and we see high temperatures. If I do this long enough, we will see the red glowing thermocouples. Don't do this at home or in the office! I can do this, but please do not. So, thermocouples. How do they work? You just connect two different metals together. That's more or less the tricky thing. Two metals or two alloys. Because of the changes in heat conductivity and heat of the possibility, electrons can move through the inner structure of a metal.

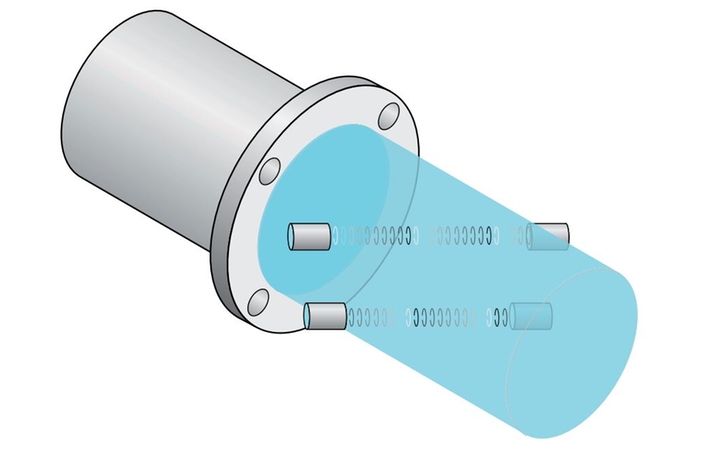

There is a small voltage produced related to the temperature. This is a thermoelectric effect also known as Seebeck effect, who discovered this. It's really easy to make. You just weld two metals together, this is a hot junction. On the other side, on the cold junction, you measure the millivolts or microvolts which are produced. Very robust design, but you see it is not a temperature measurement directly. It's a differential temperature measurement, because the hot junction and the cold junction, and what you measure is the difference between both of them. To measure the real temperature we need to know the temperature of the cold junction. We need to know the characteristic curve of the material, and then we can calculate what is the temperature at the hot junction. This is a general principle of a thermocouple measurement. The thermocouple voltage is quite small, microvolts or millivolts, and this needs quite accurate electronics in the temperature transmitter.

There are several already standardized thermocouple pairs, two different alloys or metals. Let's focus on a few! The most popular one is called type K, which is nickel chrome nickel. You see here at 1000 degrees of temperature difference we will have a signal of 45 millivolt. This looks quite linear. For higher temperatures chrome nickel is not suitable any longer, you have to switch to noble thermocouples which is typically platinum. Platinum together with rhodium. The most popular here is type S. Type S is platinum on the one side and platinum rhodium on the other side, and for example at 1500 degrees Celsius of difference we have only 15 millivolt of signal. You can see here this is a clear curve. It's not linear, so there is a quite complicated behavior in between. Especially if you go to negative temperatures, you clearly see that there is a curvy behavior of thes thermocouples.

Obviously platinum is quite expensive. You only take this if type K is not longer suitable, especially at higher temperatures. You have to expect a drift and the literature says this could be three to six percent of the reading in a year. Live with this! How can this be? How does this work in real life? The theory behind is a thermocouple consists because of the difference between two new wires, two new alloys. In this example if a new thermocouple, one wire is red, the other is blue, because their alloys are different. This difference is producing the Seebeck voltage, the thermoelectric effect. After a year in red glowing environment, strange things could happen. Because these two alloys exchange material. So after half a year, after one year, it's not red and blue any longer. It's 50 shades of violet, because for example the chromium "walks" from one side to the other side.

At the end the alloys come closer together and so they produce less thermoelectric voltage. In the result, the produced voltage is too small and so we have a negative deviation of the sensor. This can happen through the gas phase this can happen through diffusion between these two alloys, through the mineral insulated cables. There are really weird effects and I learned this from my customer visits in glass factories especially what can happen. What can you do against this? Really nothing... this diffusion is triggered by the temperature and the only way you can be sure that your temperature measurement is accurate, as you have seen in the standard in the previous episode, the standard is only valid for new wires. You have to exchange thermocouples quite regularly if you're you're operating them in a safety critical application. That's the only thing you can do, exchange!